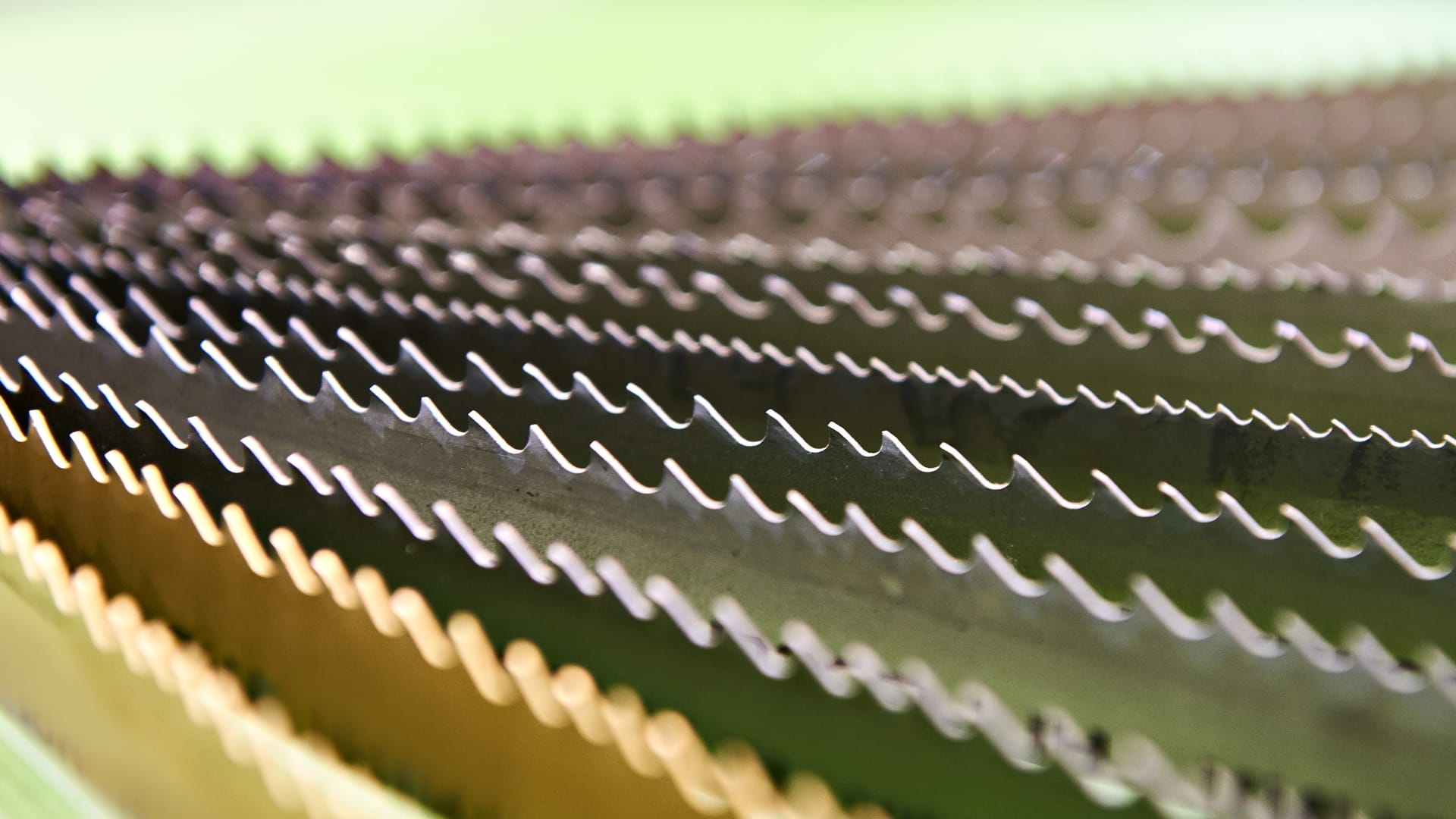

Tailor-made wire solutions for the saw and cutting blade industry

Our wire solutions are meticulously crafted to accommodate the diverse needs of the saw and cutting blade industry. Engineered with precision, durability, and adaptability, they are developed to enhance the functionality of your products performance.

Our steel wire guarantees an extraordinary performance when it comes to sharpness and edge retention. Designed with well-balanced relation between ductility and tensile strength means that the blade is flexible without breaking and resist elongation.

Quality and innovation

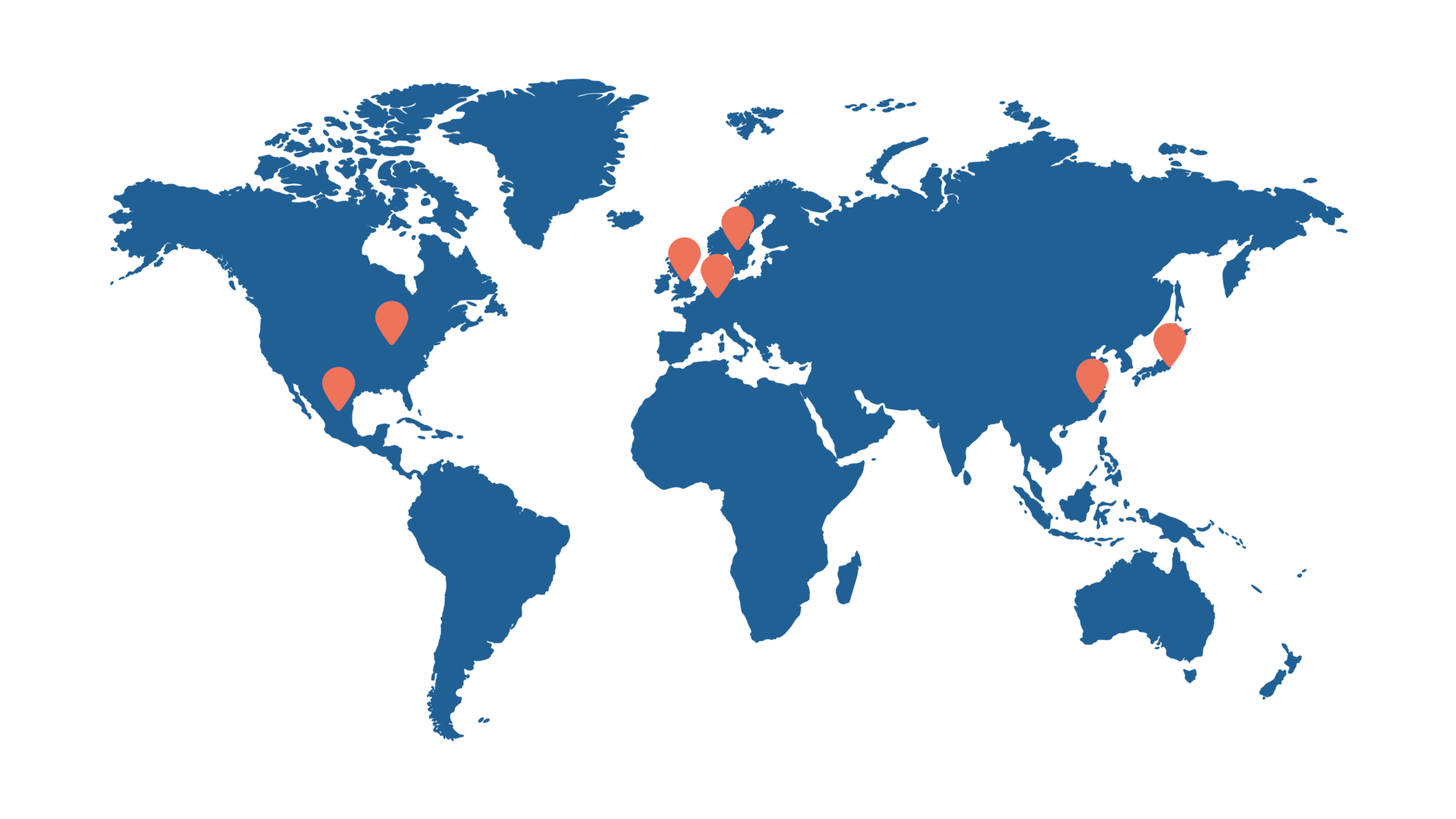

At Suzuki Garphyttan, we are committed to driving innovation and upholding the highest quality standards. Each coil of wire we produce undergoes testing to secure quality. The quality certificate accompanying every shipment is secure the material is according to customer needs and demand.

Recognizing the unique requirements of each saw and cutting blade manufacturer, we offer customized steel wire solutions that suit your specific needs. Our bespoke solutions retain the key properties of durability, edge retention, ductility, and low friction while being tailored to meet your precise production requirements.