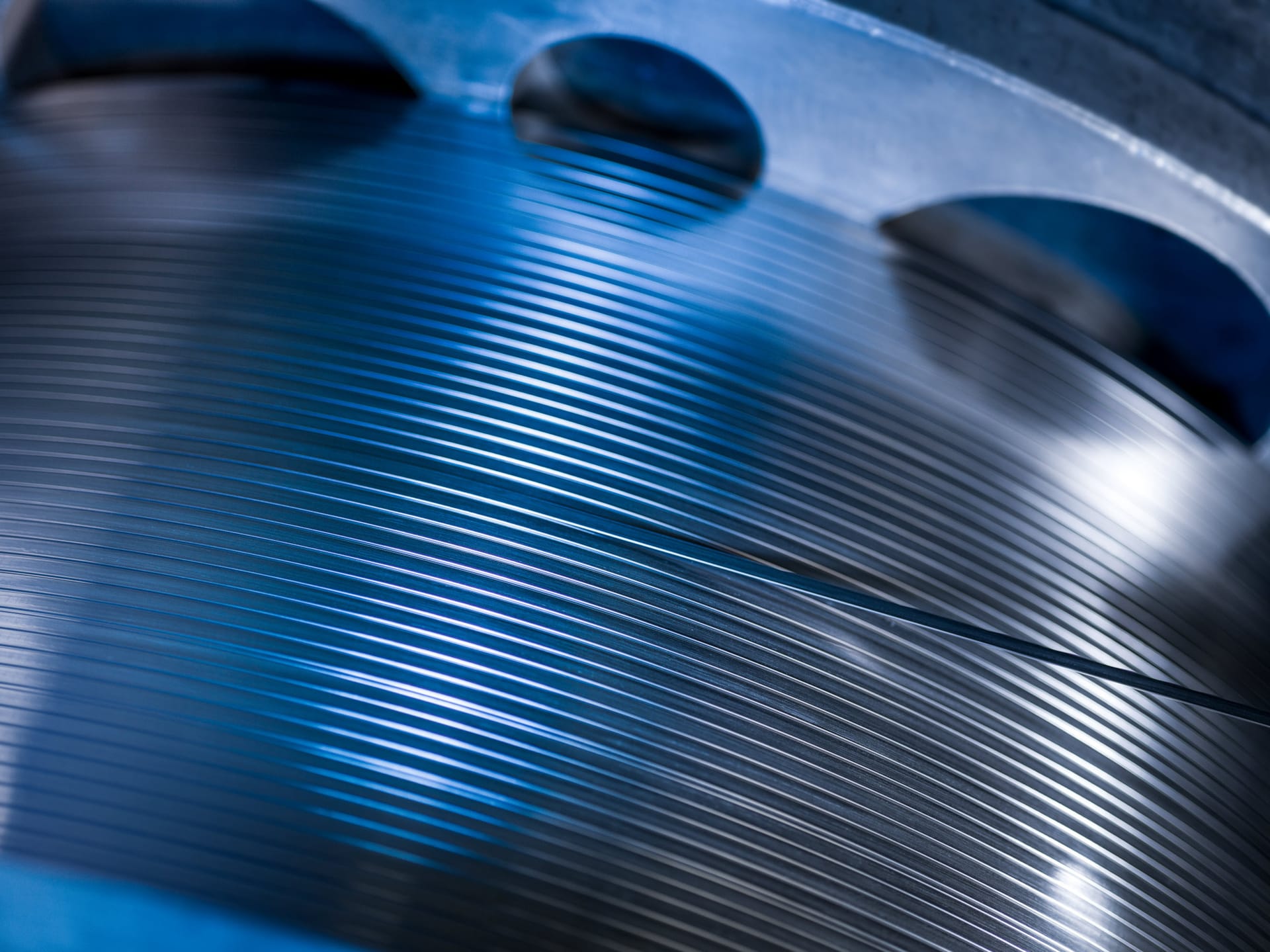

Quenched and tempered

Our quenched and tempered process is engineered for performance and care. Through precise heat treatment, we refine the steel’s microstructure to deliver exceptional strength, durability, and fatigue resistance - all while applying rigorous safety and environmental controls. We quench under carefully controlled conditions to generate a hardened (martensitic) structure, and then temper to optimize toughness, relieve stresses, and reduce brittleness. This balance ensures that our wires can endure demanding service without failure.

Responsible operations and reliable performance

We manage quenching media and operations to minimize risk and waste. Our process includes fire safety measures, careful quench monitoring, and responsible disposal or recycling of quench oils and residues. By controlling every heat-treatment step, we reduce property scattering and ensure consistency—even for critical applications. This level of quality is indispensable in sectors like automotive, mechanical engineering, and safety-sensitive components.

Our most recent development is our oil and lead free hardening, currently implemented in our Site in Suzhou, China.

Our capabilities

Optimized microstructure

Through precise control of heating, quenching, and tempering, we achieve a fine-tuned microstructure that balances hardness, ductility, and toughness. This ensures our wires can handle high stresses while maintaining flexibility and long service life.

Safety and environmental care

We operate with strict safety protocols and environmental responsibility. Quench media are carefully monitored, fire-prevention systems are in place, and all residues are treated or recycled responsibly. This minimizes risk while supporting sustainable production.

Consistency in quality

Advanced monitoring and process control reduce scattering in mechanical properties, securing uniform performance from coil to coil. This consistency is critical for customers who rely on repeatable, dependable wire performance at industrial scale.