Wire technology

Customized solutions

We understand the uniqueness of each application. Our approach is centered around crafting tailored solutions.

Innovation

Our R&D efforts keep us at the forefront of industry advancements, allowing us to enhance our products and services.

Sustainability

We prioritize sustainability in all of our processes, aiming for minimal environmental impact.

Quality

Through quality checks and compliance, we maintain a uniform quality for every product.

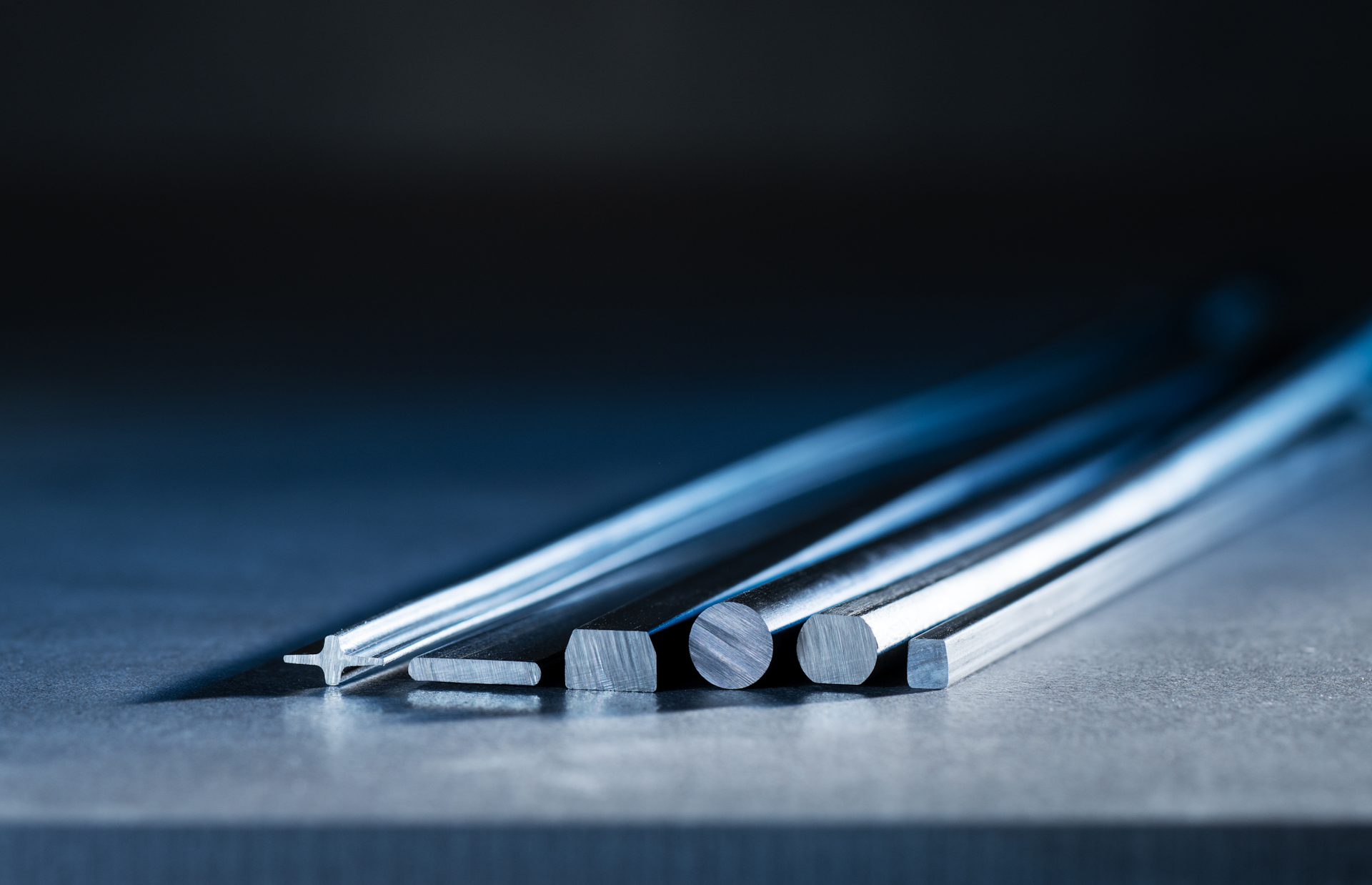

Shape & size

We transform raw materials into refined, high-performance steel wire products. We offer a variety of shapes and sizes. Our size range is vast, covering ultra-thin wires to large diameters, ensuring we can cater to your unique requirements.

Cold rolling

Cold rolling is a sophisticated process conducted at room temperature. We are forming the steel wire with utmost control to enhance strength, geometrical precision, and surface finish. Making them ideal for applications with high requirements in wire forming and end-use. Our cold rolling process covers flat and complex shapes according to your needs.

Cold drawing

Precision is at the heart of our cold drawing process. This technique refines the surface finish and ensures the dimensional accuracy of our wires. The result is a wire with a smooth finish, precise dimensions, and improved mechanical properties. By using in-house tool-making equipment we optimize performance in our production and live up to the high requirements of our customers.

Heat treatment

Patenting, spheroidizing, and annealing are some heat treatment steps in our wire production process. Patenting improves ductility and toughness and in some cases restores the microstructure for further cold working. Spheroidizing enhances formability, and annealing increases softens the material and improves flexibility.

Oil tempering

Our oil tempering process ensures optimal mechanical properties for the wire, making the wire able to withstand demanding conditions in both subsequent forming steps and application performance. This process, which follows cold working, is meticulously controlled to achieve the desired properties for your application.

Quenched & tempered

Our quenched and tempered process is designed to eliminate hazardous substances, providing a robust and responsible solution for demanding applications. This method enhances the performance of our wires, ensuring they meet the highest standards of quality.

Lab services

We cover a wide spectrum of activities, from incoming inspection of wire rod materials and advanced material investigations to corrosion testing, fatigue testing, and supplier quality assurance. By combining deep technical expertise with state-of-the-art analytical methods and strong partnerships with leading research institutes, we acquire fast reliable insights that drive performance and excellence.

Quality and surface testing

Before delivery, our steel wire undergoes final testing to secure quality and reliability. Each batch is inspected through visual checks, dimensional measurements, and mechanical testing. Advanced non-destructive methods such as Eddy Current (EC) testing scan the wire continuously to detect even the smallest surface flaws, while conductivity measurements verify alloy integrity and heat-treatment accuracy.

Machine & tool making

By having a tight collaboration with machine suppliers and also internal development of equipment we can ensure that we are in the forefront of technology. We continuously work to improve safety and make our process more environmentally friendly. In-house tool-making for both dies and rollers ensure that we keep improving our forming technology and can support customer projects.

EXPLORE >>>

Uniting strength to streamline wire manufacturing

Strengthening the world

Advanced lab services, testing, and analysis

New industry standards through supplier development