Interested in this product?

Contact us for further discussions. Our dedicated team is ready to assist you, understand your wire product needs, and answer any queries. Submit your request below.

Product request

High formability

High ductility ensures that you can form the wire according to your needs

Carbon Steel

Suitable for various applications with moderate requirements in fatigue and wear resistance.

Surface finish

Available in surface conditions according to your need.

Product information

Technical specification

Mechanical properties

Chemical composition

Surface conditions

Additional

Documents

| Property | Value | |

|---|---|---|

| E modulus of elasticity | 206 kN/mm² | |

| G modulus of shear | 79.5 kN/mm² | |

| Density | 7.95 kg/dm3 | |

| Microstructure | Tempered martensite with no ferrite | |

| Execution (flat) | Rolled on 2 sides | |

| Execution (shaped) | Rolled on 4 sides | Profile drawn |

| Camber | Max. 4 mm measured on 1 m length. | |

| Coil set | Max. 20 mm measured on 1 m length. |

Steel grades and product standards

| Nearest equivalent product standards | EN 10270-1 | |

| Nearest equivalent steel grades | EN/DIN 1070 | AISI/SAE 1070 |

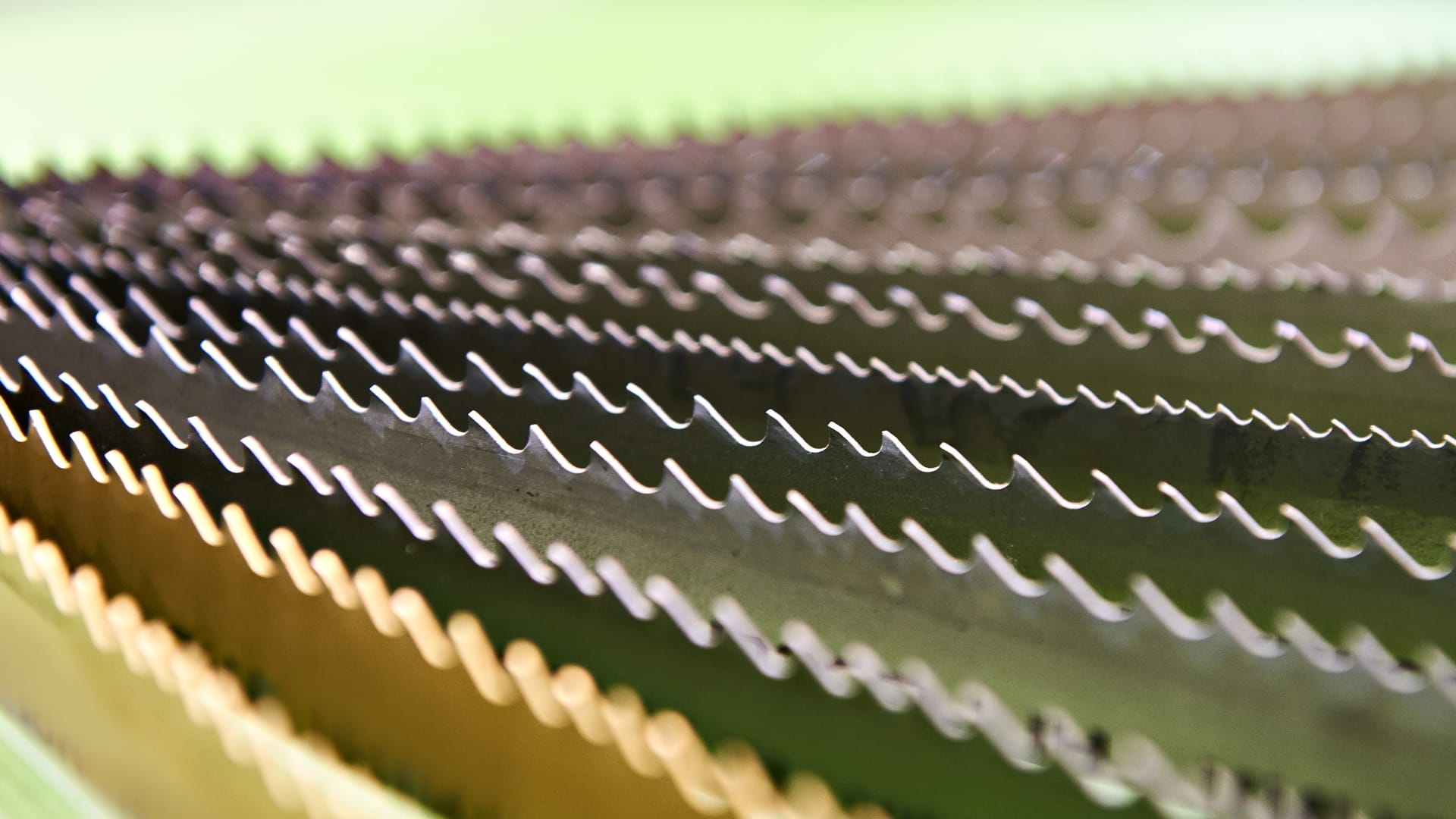

Applications using GARBAFLEX 75

×

![]()