| Element |

Weight % |

| C |

0.50% - 0.70% |

| Si |

2.10% - 2.40% |

| Mn |

0.30% - 0.70% |

| P max. |

0.020% |

| S max. |

0.030% |

| Cr |

1.10% - 1.40% |

| V |

0.05% - 0.25% |

| Mo |

0.05% - 0.25% |

| W |

0.05% - 0.25% |

Cleanliness in steel

The presence of non-metallic inclusions in the wire rod is inspected for every heat in accordance with the Suzuki Garphyttan method by the steel supplier.

Before release for production, Suzuki Garphyttan performs non-metallic inclusion inspection for every fifth heat. The criteria for supplier inspection and releasing inspection are the following;

For wire rod samples: Inclusion size max. 15 µm down to 1 mm below surface. Inspection area 1 000 mm2.

| Inclusion size, surface |

5–10 |

> 10–15 |

>15 µm |

| Max. number of inclusions |

50 |

7 |

0 |

As stated by IVSWMA, International Valve Spring Wire Manufacturers Association, it is likely to find occasional inclusions in valve spring quality steel of a size larger than 30 µm.

Surface condition – non-destructive testing

In the standard size range 2.00 - 5.00 mm the wire is tested continuously in Eddy Current equipment to a surface level of ≥ 40 microns. Other wire sizes on request.

Surface condition – end sample test

The wire is end sample tested by means of etch testing and binocular inspection as well as microscopical inspection of the material structure. Max. permissible depth of partial surface decarburization and surface defects, 0.5% x wire diameter. No complete decarburization allowed.

Heat treatment

As soon as possible after coiling, the springs should be stress relieved. Depending on nitriding temperature used later in the spring manufacturing process, this temperature may be decreased.

Hot presetting

After shot peening, the springs should be hot preset or stress relieved. In order to reach optimum fatigue and relaxation properties, the springs must be preset at an appropriate stress.

Shot peening

In order to obtain optimum fatigue properties, the process time should be adjusted to get a complete treatment. Size of shots should be adapted to wire dimension, pitch and shot peening equipment.

For nitrided springs with an extremely hard surface zone, it is important to use a shot peening media with high hardness.

Shot peening of the inside of the spring coils is particularly critical.

Spring conditions for test

| Spring conditions for fatigue and relaxation tests (specially designed test spring) Diagram 1 and 2: |

| Wire diameter |

Ø 3.85 mm |

| Diameter external |

26.95 |

| Spring length, I0 |

53.0 |

| N active |

4.15 |

| Spring index |

6.0 |

| Stress relieving |

| Temperature |

450°C (790 ±10 °F) |

| Time |

30 minutes |

| Soft shot peened |

| Speed |

20-30 m/s |

| Time |

5 min |

| Shot size |

0.8 mm |

| Nitriding |

Gas nitriding |

| Temperature |

450-470°C |

| Time |

5-20 hours |

| Aim for surface hardness |

Min. 850 Hv |

| Aim for core hardness |

Min. 610 Hv |

| Compound (white) layer |

Max. 1 µm. |

| Shot peening (triple shot peening for nitrided springs) |

| 1st treatment |

Pressure 0.3 MPa with RCW shoot size 0.6 mm (hardness 800 Hv) for 20 minutes. |

| 2nd treatment |

Pressure 0.3 MPa with RCW shoot size 0.25 mm (hardness 800 Hv) for 10 minutes. |

| 3rd treatment |

Pressure 0.2 MPa with fine shoot size (hardness 700 HV) for 10 minutes. |

| Aim for Almen arc-height |

0.55 – 0.60 mm |

| Hot presetting |

1500 N/mm2 (nitrided springs) |

| (theoretically set) |

1300 N/mm2 (not nitrided springs) |

| Temperature |

200°C (max. 250°C) |

| Time |

10 minutes |

Relaxation and fatigue properties

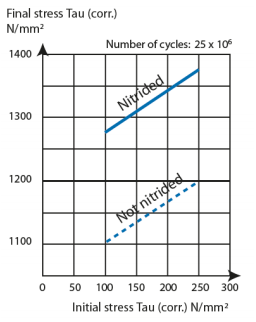

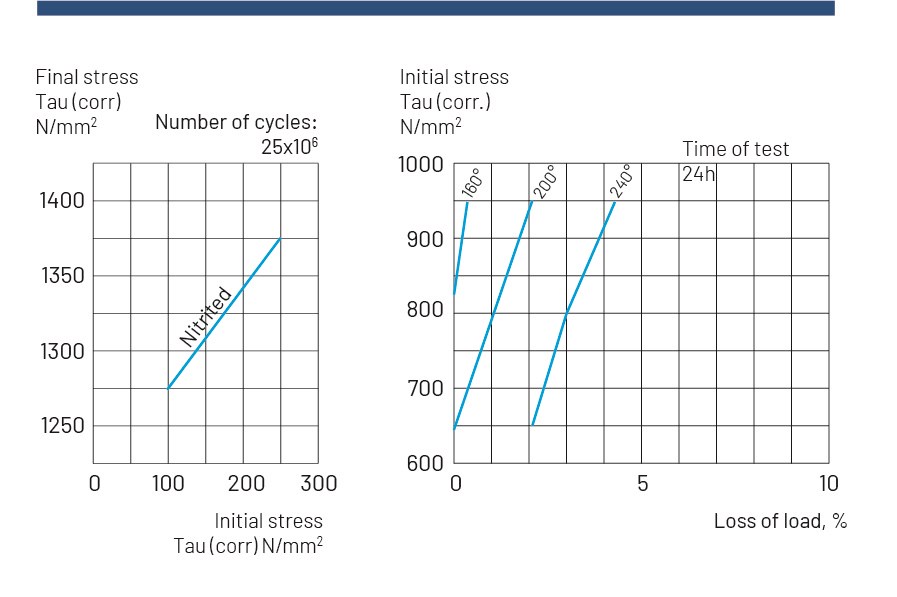

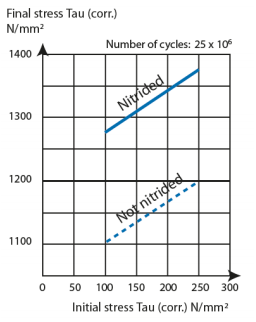

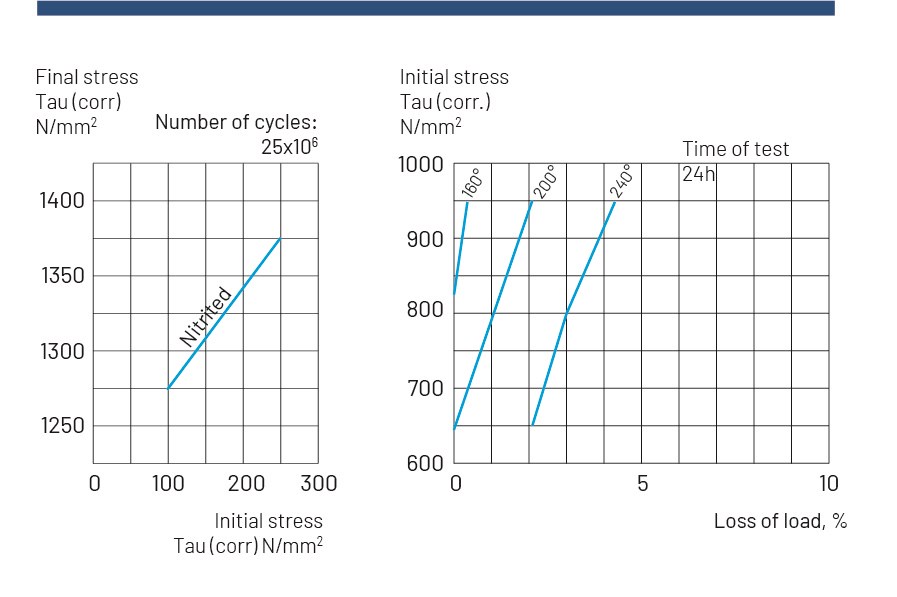

In diagram 1 the fatigue properties of this grade are illustrated in a Goodman-diagram, based on a special test spring design.

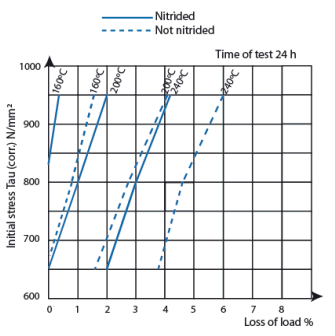

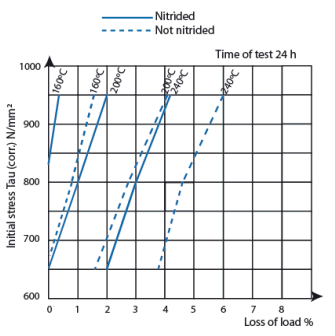

Diagram 2 shows the relaxation properties (loss of load) of nitrided springs made from OTEVA® 101 SC wire subjected to static compression at different temperatures, nitrided/not nitrided.

Decarburisation

No total decarburisation. Partial decarburisation (no continuous zones) max. 1.2% of a corresponding round wire dimension.