Products

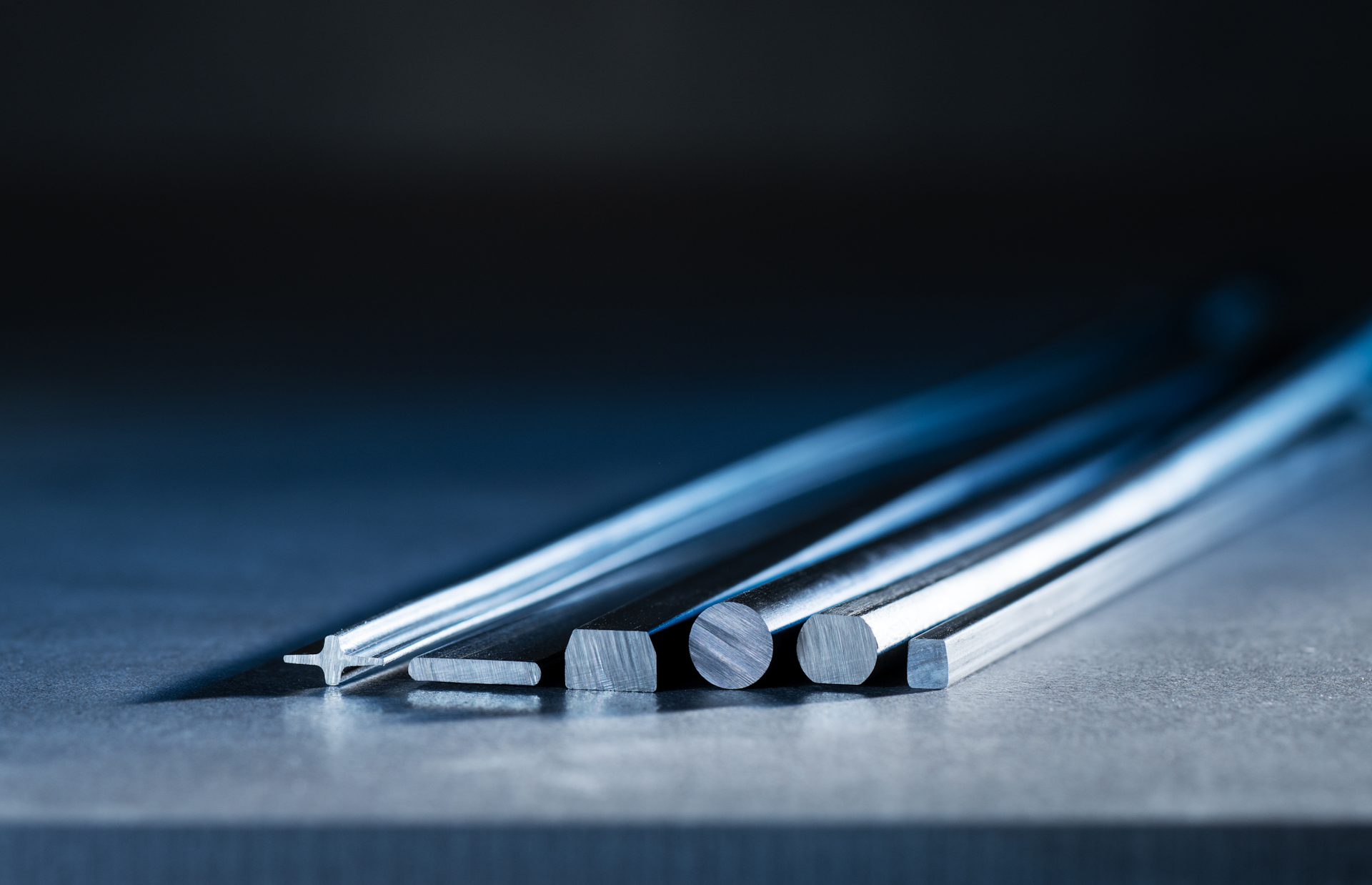

Discover our range of high-quality steel wire products, designed to meet the diverse needs of industries worldwide. We understand that every application is unique, which is why we specialize in customizing wire solutions to suit your specific requirements.