Comments from our CEO

Suzuki Garphyttan shows resilience in 2023

Despite challenges in the European market, including a necessary reduction of the workforce in Sweden, Suzuki Garphyttan remains resilient. Record-high volumes in China and a steady market in North America provide a good foundation for recovery.

As we transition into a new five-year phase, the commitment to create a great workplace, pioneering wire solutions, and driving growth and profitability remains unwavering. We are diversifying, expanding and investing in our people, sustainability and productivity, ensuring our strong foundation and position, maximizing value for our stakeholders.

Even though 2023 didn't quite hit the highs we wanted, it was still a good year with the third-highest production volume ever. Closing the year a little bit over 69 000 metric tonnes, we maintain a cautiously optimistic outlook for 2024.

Ad Raatgeep

President and CEO

Billion SEK in revenue

Metric tonnes of wire produced

Years of experience

Highlights

2023

A history of successful sales

In March, we celebrated 50 years since opening our sales office in Germany, at the center of Europe's automotive industry. Thanks to all who've joined us on this journey so far!

New for 2023

Bright is the new black! Highly requested from our customers, we can now offer bright drawn stainless steel wire.

With a 21 percent reduction in accidents and a 32 percent increase in preventive risk observations, our commitment to safety is stronger than ever.

A more easily accessible product catalog

In 2023, we launched a new website with lots of improvements. Now products and offerings are more easily accessible.

Thanks to the exceptional dedication of our hardworking employees and a strong market, our business in Suzhou, China did a fantastic result in 2023, reaching all-time-high figures.

of our customers see us as their future partner

In the annual customer survey, 75 customers submitted answers on a wide range of customer satisfaction topics. We greatly appreciate this invaluable input.

Product news

New cold-drawn wires in 2023

This year, we added cold-drawn wire to our product lineup. This aligns with our journey to offer a wider range of spring wires for diverse industries. Learn more about this exciting development and its role in our future plans.

Product news

Spheroidized wire breakthroughs

We've made significant advancements in spheroidized wire, with the textile industry as the largest customer segment. We've begun serial deliveries and explored new applications through successful trials. Our focused approach with key customers has allowed for tailored solutions and invaluable feedback.

Additionally, we've expanded our range with high-carbon content wires, offering enhanced wear resistance. Going into 2024, we are preparing to offer finer sizes.

Capacity

New stainless steel drawing machines - a boost for finer sizes

Suzuki Garphyttan steps into a new era with the launch of new stainless steel drawing machines. This strategic upgrade will allow us to draw finer dimensions, as well as enhance both our production capacity and operational flexibility. This investment is a testament to our long-term commitment to the stainless and high-alloy product segments.

Quench and tempered

Sustainable wire hardening: Suzuki Garphyttan's ongoing success

Our journey towards environmentally friendly wire hardening continues to show good results. By eliminating lead from our processes, we not only reduce hazardous substances but also remove the possibility of lead contamination on our wires.

This is a significant assurance for our customers and OEMs, prioritizing both safety and environmental responsibility. Moreover, this method of hardening improves the mechanical properties of our wires, demonstrating our dedication to innovative, sustainable solutions.

Capacity

Global expansion of shaped wire capabilities

Suzuki Garphyttan is now offering shaped wire from every production region, with key advancements in China including series deliveries and capabilities for spool and paper core delivery. We've enhanced surface quality and trained our production teams, reflecting our commitment to localizing our full product range in each region.

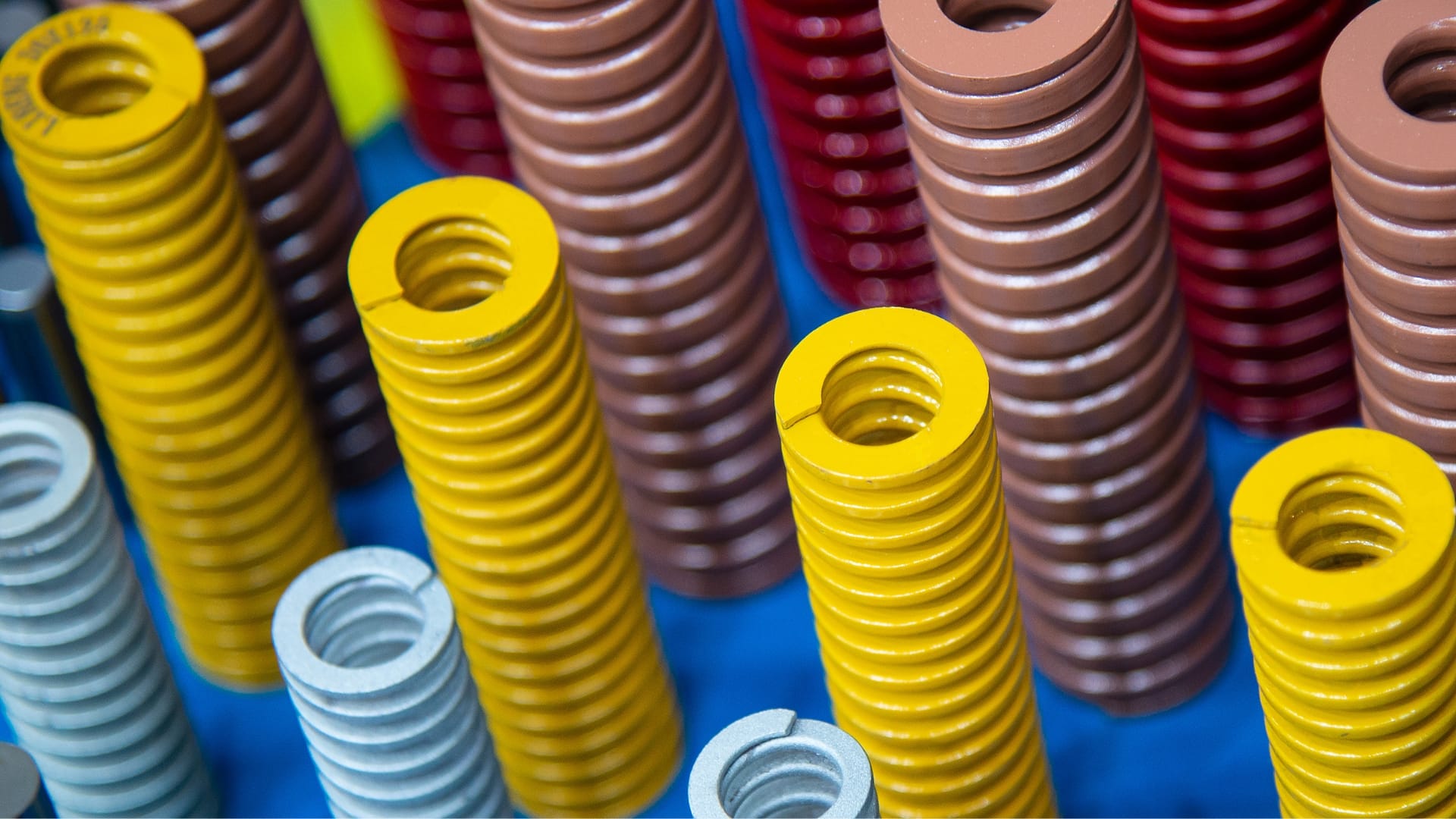

This expansion serves diverse applications like retaining rings and die springs, meeting varied market needs with high-performance shaped wire.

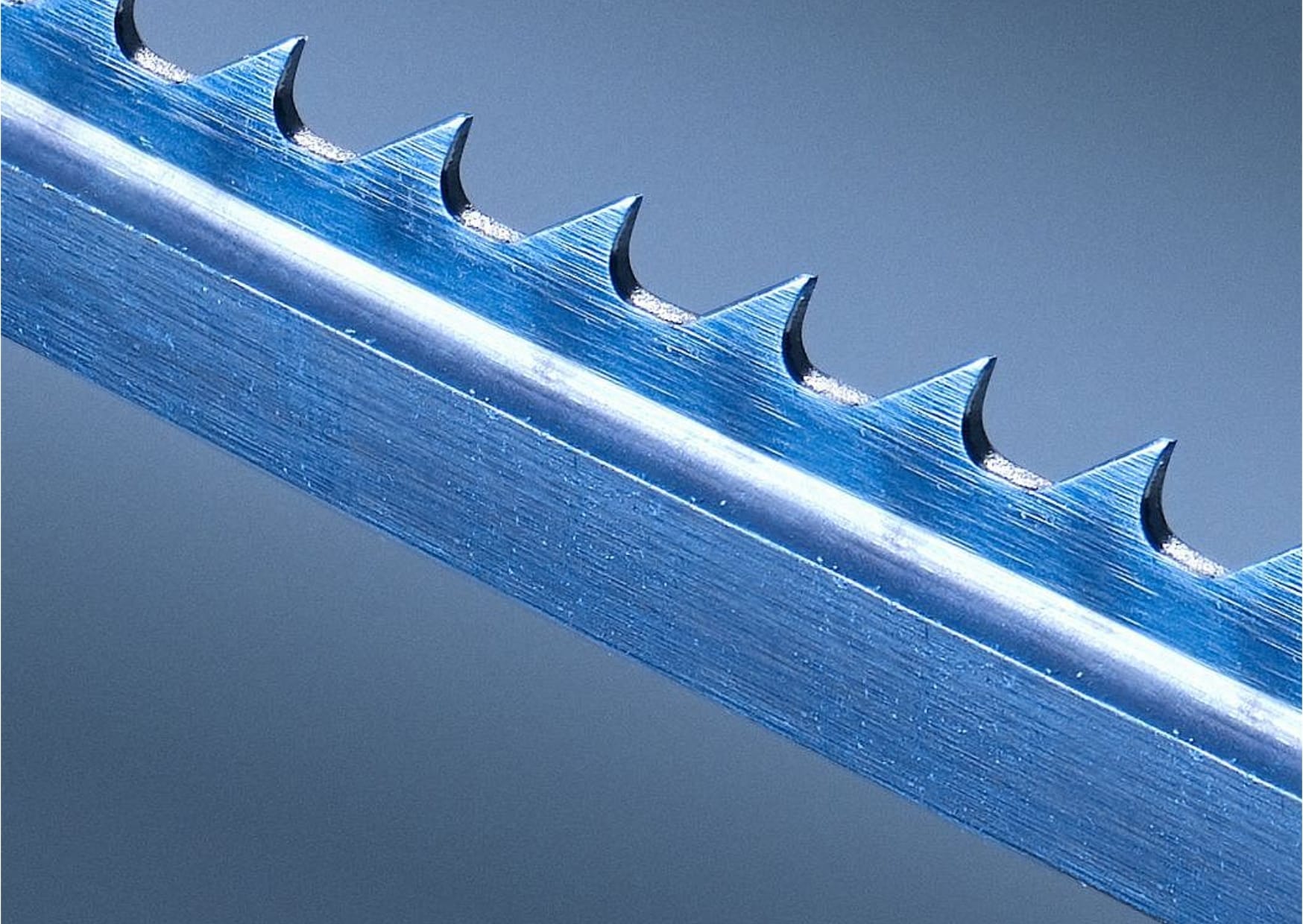

Product news

Introducing bright drawn stainless steel wire

Now we can offer bright drawn stainless steel wire, significantly reducing residual on the wire surface. This development is vital for applications with strict requirements for cleanliness and surface appearance.

The bright, fine surfaces of our wires not only improve corrosion resistance but also facilitate easier cleaning, which is important for applications like medical equipment and conveyor systems in sanitary environments.

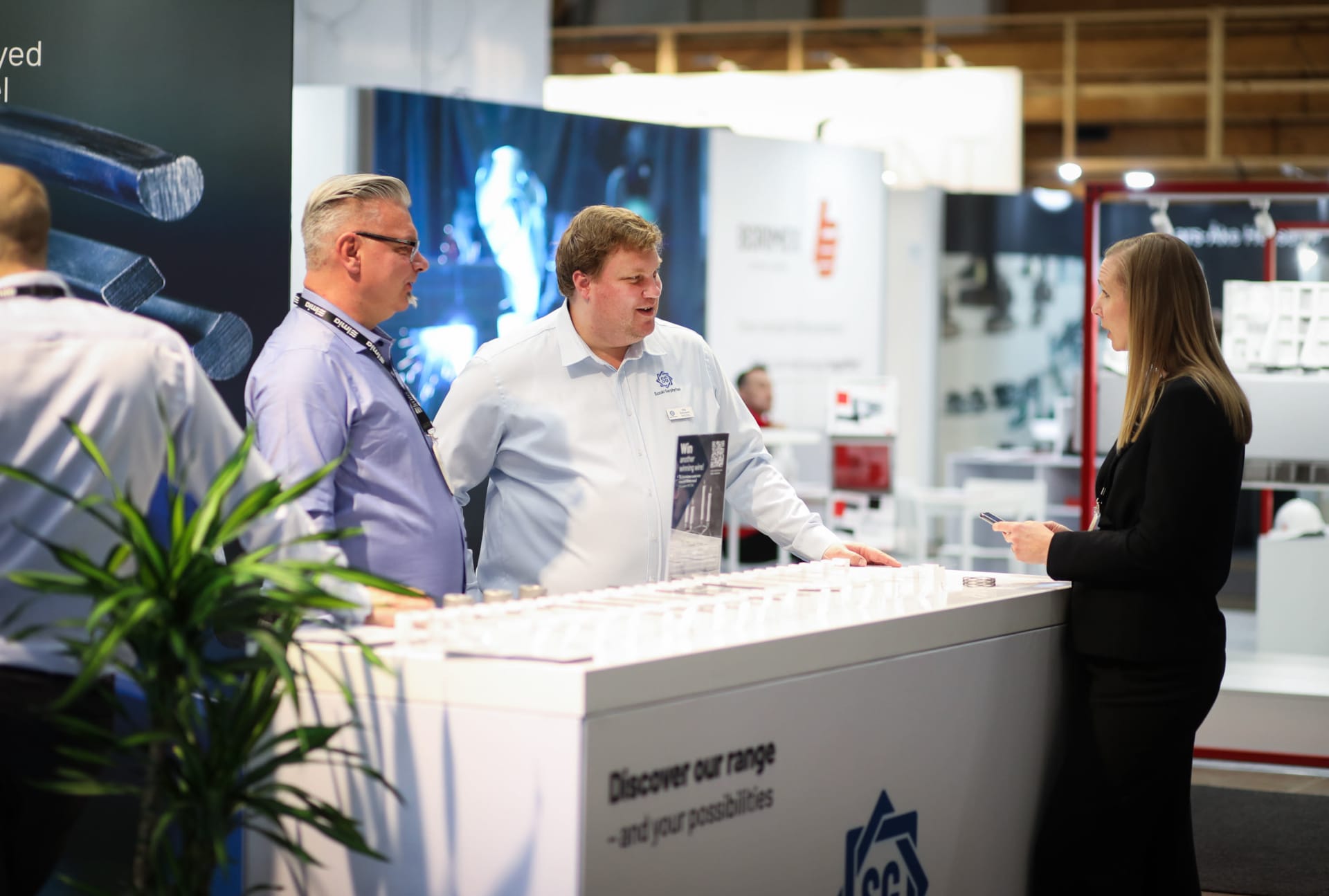

Customer case

Unified pursuits between Lesjöfors and Suzuki Garphyttan

Explore the collaboration between Lesjöfors and Suzuki Garphyttan, focusing on sustainable innovation in spring technology. Read more about the shared commitment to innovation and environmental responsibility and how it shapes our work.

Shaping the wire of tomorrow

Yohanna Greenlee

Quality Assurance Engineer, South Bend, USA

"Diversification, technological improvements, increased productivity and globalization are KEYS to our future!"

Henrik Pettersson

Site Manager, Garphyttan, Sweden

"Through continuous adoption of best practices and a commitment to sustainability, we enhance both productivity and quality, achieving a win-win effect. Together, our pursuit of operational excellence paves the way for a better tomorrow."

Ola Ericsson

Program Manager Non-Automotive, Garphyttan, Sweden

"Our spring wire withstands up to a billion compression cycles without fatigue. The stringent demands from the automotive sector are in our blood. Now, we are applying our expertise to develop products within other segments."

UN Global Sustainable Development Goals

How we align our work with the goals

Suzuki Garphyttan supports UN Sustainable Development Goals, particularly focusing on goals related to health, education, gender equality, water and sanitation, clean energy, economic growth, responsible consumption and climate action. We prioritize CO2 reduction, sustainable energy usage through solar panels, and efficient use of raw materials to fulfill our commitment to these global goals.

We align our environmental goals with our vision "Together for a better tomorrow" and employ the Triple Bottom Line approach, balancing environmental, social, and financial sustainability. Our strategy integrates sustainability across the company, prioritizing areas with the highest impact.

Four out of five sites are certified

Improved health and safety

This year, we certified our largest production site in Garphyttan, Sweden, according to ISO 45001:2018 standards for occupational health and safety. Moving forward, our commitment is to extend this certification to our one remaining site, bringing all our production facilities in line with requirements.

Accident-free by 2025

Intensifying our safety work

In 2023, the trend of decreasing workplace accidents continued, alongside a rise in preventive risk reporting, indicating progress in safety. Our commitment to safety was highlighted by conducting Safety Weeks quarterly. We started training programs focused on safety mindset and culture, aiming for a safer workplace by addressing both individual and organizational aspects. A significant improvement was achieved by closing more risk observations than in the previous year.

Suzuki Garphyttan for a sustainable tomorrow

Edwin Grönkvist

Global Sustainability Manager, Garphyttan, Sweden

"It's crucial that we manage and prioritize sustainability issues. This includes conserving the Earth's resources. Within the steel industry we have significant opportunities to make an impact – if we do it right."

Thomas Wrenninge

Global Sourcing Manager, Garphyttan, Sweden

"In 2023, we've seen major developments in Green Steel. Several European steel suppliers obtained funding to construct Green Steel plants. The introduction of the EU's carbon border tax ensured that European manufacturers remain competitive against non-European suppliers not investing in Green Steel."

Ilaria Menti

Application Manager, Garphyttan, Sweden

"A great strength of our strategy lies in our triple bottom line approach, which considers environmental, social, and financial factors. We dare to take steps to address global challenges while valuing the well-being and safety of our employees."

A great place to work

Suzuki Garphyttan boosts personal growth opportunities

At Suzuki Garphyttan we are dedicated to cultivating an engaging, diverse, and inclusive workplace filled with exciting career opportunities. As we venture into fresh business domains, we're working tirelessly to fortify our global team, equipping them with new skills and enhancing the capabilities of our existing talent pool.

At the end of the day, it's the expertise and dedication of our skilled workforce that drives innovation and excellence across our products and operations.

As we set sights on 2024, it is all about how we can grow, improve, and collaborate together. All is connected. A thriving workforce leads to better products and, ultimately, increased customer satisfaction.

Garphyttan Academy

Wiring up employee skills with Suzuki Garphyttan Academy

At Suzuki Garphyttan it is all about expanding into new business areas with a strong global organization. Now we are intensifying the efforts to equip our employees further with skills needed for success.

To support our employees' growth and the company's transformation, we're introducing The Suzuki Garphyttan Academy. This initiative will facilitate ongoing employee development, ensuring that we remain competitive in the ever-evolving business landscape. The Suzuki Garphyttan Academy will include many initiatives starting with investing in leadership and project management development, with plans for an employee program in 2024.

New Onboarding program

A strong start for all

A warm welcome and an effective onboarding is crucial for all members of a company. That's why we've embarked on a global onboarding journey—a project we started 2023. Our ultimate aim is to craft a seamless experience for our new team members, nurturing swift adaptation and a strong sense of belonging.

These continuous efforts are all about enhancing retention, productivity, and the overall success of our organization. By providing our employees with the essential knowledge and the resources they need, we hope they will feel a sense of belonging and valued contributors to the Suzuki Garphyttan team.

Stronger together

Crystal Flores

Quality Manager, San José Iturbide, Mexico

"This global workplace really gives me the opportunity to learn, share and be part of many different projects. Working at Suzuki Garphyttan is challenging, inspiring and innovative."

Ludvig Björkman

WOW-coordinator, Garphyttan, Sweden

"In Garphyttan, I am always well received by all the nice and knowledgeable colleagues, which makes it fun to go to work."

Ulf Pelow

Global Organizational Development Manager, Garphyttan, Sweden

"Our priority at Suzuki Garphyttan is to create a workplace where the development of leadership skills, effective collaboration, and personal growth are at the forefront. A place where we can be safe and confident, think in new ways and use our differences to succeed together."